|

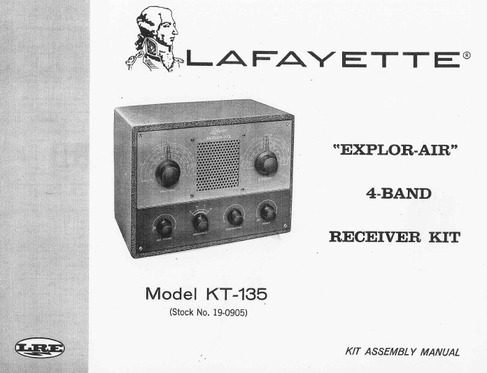

Lafayette KT-135 EXPLOR-AIR radio

kit |

|

|

|

|

|

|

|

|

In the 1960s, Popular Electronics

hosted a monthly column called "Short Wave Listening."

Occasionally a KT-135 would appear in the photos. On the

left is Mike Byers of Shelby, NC whose primary receiver was

a Lafayette KT-135 (from October 1965 issue.) The photo on

the right, from August 1964, shows Robert Mladenka of

Flatonia, Texas, whose "backup" receiver was a Lafayette

Explor-Air.

Notice the newer style knobs on Mike Byers' 1965 KT-135. |

|

|

|

|

|

|

|

From Electronics Illustrated,

November, 1963.

This is John Sullivan of Greenwich,

Connecticut. He's operating a

Hallicrafters S-120, but you

can see he started with a KT-135. |

From Popular Electronics, September, 1964.

Edward Jacobson of Westbury, NY is using a Lafayette HE-30

receiver,

with his KT-135 in "standby service." The HE-30

was also a kit. |

|

|

|

|

|

|

|

Gary Confrey of Killingworth,

Connecticut.

A Lafayette KT-135 sits on top of a Lafayette "Starflite"

transmitter.

Photo from the May, 1966 issue of Popular Electronics. |

Listening post of Grant Power, VE2PE6K of

Montreal, Canada.

For some reason he isn't in the photo, but the KT-135 is.

Photo from September, 1963 issue of Popular Electronics. |

|

|

|

|

|

|

|

Popular Electronics, July 1969. |

Popular Electronics, May 1968. |

|

|

|

|

|

Popular Electronics, November, 1963.

Grant Power, VE2PE6K, in Montreal, Quebec. |

Dan Levine, WA2CLP, in 1967 |

|

|

|

|

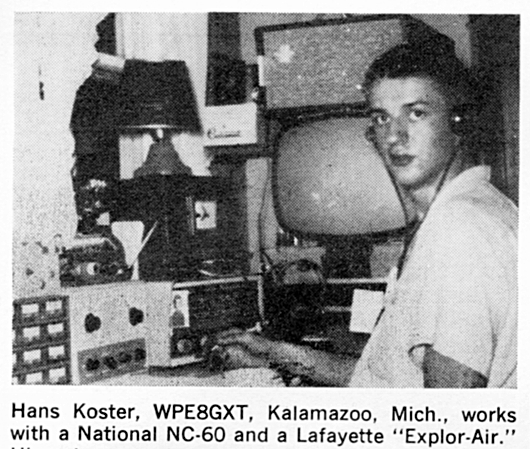

The call signs that started with the designation

"WPE" were issued by Popular

Electronics to shortwave listeners. |

|

|

|

It is interesting to see the faces

of people who built a KT-135. Makes you wonder what happened to

them. Not the people, the radios! Well, the people, too, I

guess.

Gary Confrey was about 15 years old in the photo above. The

KT-135 was his first kit, purchased at the Lafayette store

in New Haven, Connecticut. (The Starflite transmitter was

also a kit.) The KT-135 got him started in electronics and

he spent his life in that field. As of 2022 he is 72 years

old and a senior technician in a lab at an electronics

company. He is still an Amateur radio operator and lives in

Monroe, GA.

Dan Levine is still a Ham. I can't find

any information on the other people in the pictures. |

|

|

|

|

|

|

|

|

|

From spring 1969 catalog. |

|

|

|

|

REPAIR NOTES AND TIPS CONCERNING THE

KT-135 |

|

|

|

|

|

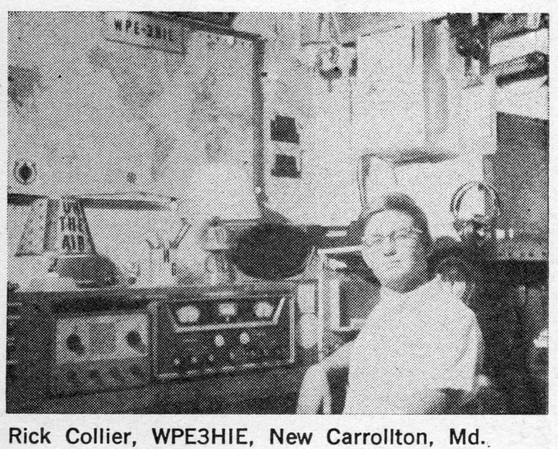

| A rebuilt KT-135. |

| Lafayette claimed that the KT-135 is

so easy to build a child who can read could do it. This is

marketing BS. Building or rebuilding a KT-135 is

NOT easy. Some were built by a 10

year olds, but that doesn't mean it's a piece of cake because you're

not 10. However, the instructions are practically

fool-proof. Any wiring mistakes or a component installed of

the wrong value will be picked up later in the assembly. |

|

|

|

|

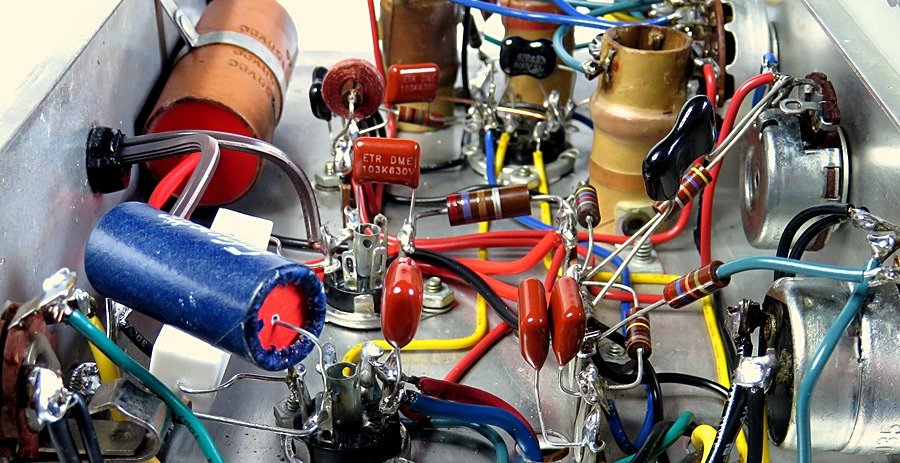

The Headphones Jack |

|

|

|

|

Notice the fiber and

shoulder washers on the headphone jack. They are

both made of the same fiber material and insulate

the headphone jack from the chassis. I've found two

sets with the shoulder washer missing. Without the

shoulder washer, the common side of the headphone

jack is connected to the chassis, which means that

one side of the speaker and audio output transformer

are also connected to the chassis.

Depending on how the non-polarized plug is inserted

into the outlet, the chassis could be "hot." When the chassis is "hot" it's sitting

at 94 VAC in reference to earth ground. Without the

shoulder washer the headphone jack is now also

"hot." The current is limited by a 100K

resistor, so it won't kill you, but what would it do

to your headphones? |

|

|

|

If necessary, you can use the fiber washer from

the antenna connector as the shoulder washer

for the headphone jack, since the antenna connector is plastic and

has a shoulder molded into it.

|

|

|

Noisy Antenna Tuning Capacitor |

|

|

|

|

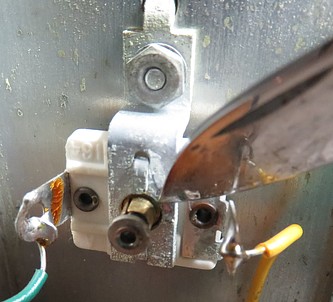

The Antenna Tune capacitor

can be very noisy. This one was so

noisy it was ruining the reception. It also wobbled

and the knob looked crooked.

The capacitor is a standard compression type, mounted in a bracket. The bracket is grounded to

the chassis. It has a 1/4 " diameter shaft attached to a

screw that projects through a brass threaded collar.

The value is 5 to 80 mmfd. In series with the

variable capacitor is a disc capacitor with a value

of 270 mmfd. This causes the total value to be 3 to

25 mmfd.

The capacitor is totally isolated from the chassis

bracket and it can't go intermittent or short out by

the nature of its construction. So what is causing

the problem? It's the

connection between the mounting bracket and the brass collar!

An ohmmeter was connected between the chassis and

the collar, and the meter swung wildly when the knob

on the front was turned.

So what? There is no connection to the actual

capacitor. Apparently, since this is

where the antenna comes in, the intermittent causes

a small electric current that the antenna picks up

and is then

amplified thousands and thousands of times. That's

my theory, at least. If you unscrew the capacitor

from the chassis and let it hang in the air, the

problem goes away. |

|

| |

|

|

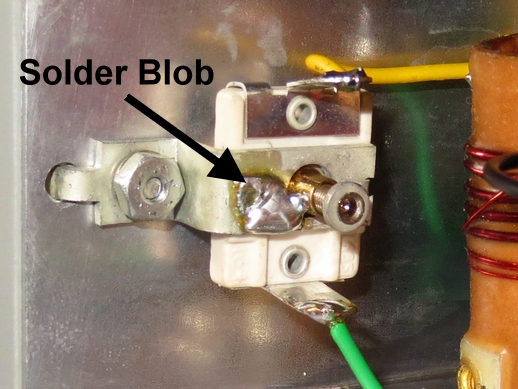

| The fix is to polish up part

of the brass collar and the mounting bracket (I used

a knife to scratch it up) and connect the bracket to the collar with

a blob of solder. This also stiffens the capacitor in

the bracket so it won't wobble. Don't solder the

screw to the brass collar! |

|

| |

|

|

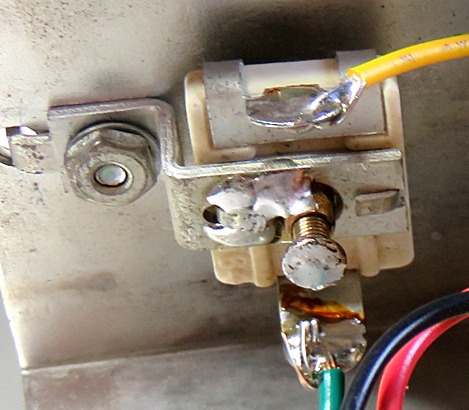

| In the left photo the

threaded shaft has been removed because it was bent. On the right is

the same capacitor put back in service. |

| |

|

|

| Scrape the steel

bracket, scrape the brass collar, then solder them together. I have

a 100% success rate with this fix. |

|

|

|

|

|

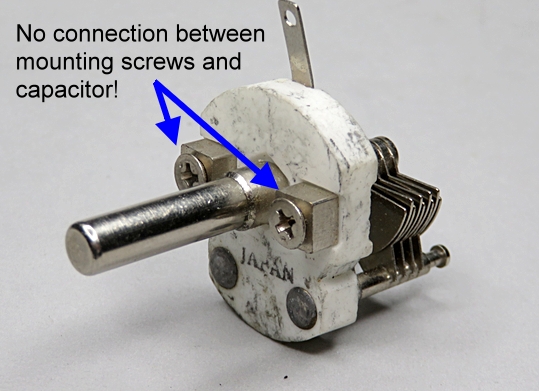

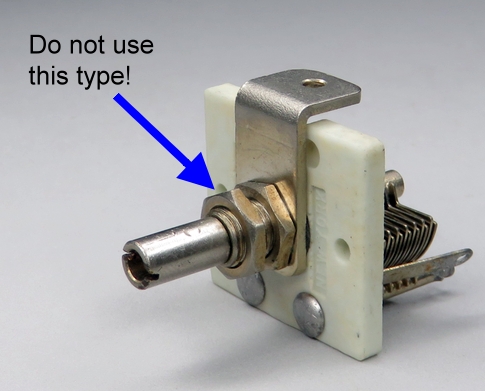

| If you are going to replace the antenna tune

capacitor, be sure to isolate it from the chassis

and do not allow the shaft to come into contact with

the front panel. Do not use the type that mounts to

the front panel using a nut around the threaded base

of the shaft. |

|

|

|

|

|

Loud Hum. Rebuild The Filter Capacitor. |

|

|

|

|

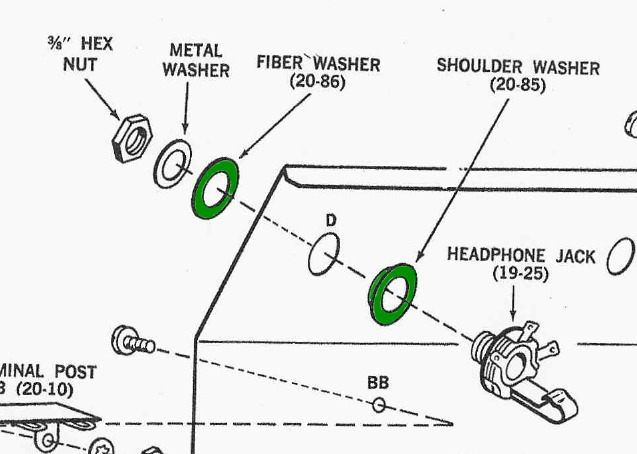

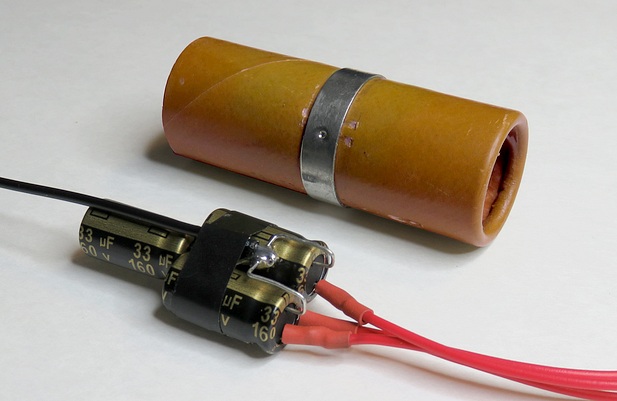

The KT-135 uses three power

supply filter capacitors encased in a single

cardboard tube, Lafayette part number 12-59. They are

each rated 30 MFD at 150 volts. After 65 years or

so, none of them work as they should, causing a loud

hum in the radio.

|

|

|

|

The filter capacitor bundle is

encased in plastic. To remove it from its housing it

is necessary to use a heat gun. You must get it very

hot. Put the three red wires in a vise and heat it

evenly with the heat gun. When it looks like it's

"sweating" it's almost ready. Grab the capacitor

using a rag (NOT YOUR BARE HAND) and pull gently.

If nothing happens, stop and apply more heat, but

don't scorch it or start the thing on fire. When

it's hot enough the casing will pull off, leaving

the guts hanging out of the vise on the three red

wires.

When you realize how hot the capacitor needs to get

before the plastic melts, you'll wonder how it

survived being encased in the molten plastic to

begin with. How did they inject the hot plastic into

the cardboard tube? |

|

|

|

|

|

|

|

|

| The three capacitors are

made of layers of metal foil insulated with paper,

rolled up very tightly. The negative side is a

single piece of aluminum foil approximately 33

inches long and 1.5 inches wide. Three 10.5 inch

strips of metal make up the positive sides. The paper should be damp or

sticky with electrolyte, but in almost every case it

is

bone dry due to age. |

|

|

|

|

|

|

| Three 33uF caps rated at 160

volts may fit perfectly

inside the casing, and the voltage rating is higher

than the original 150 volts. 250 volt caps won't fit. Observe

the polarity carefully. A modern filter capacitor

connected backwards will be instantly destroyed when

power goes through it. |

|

|

|

|

|

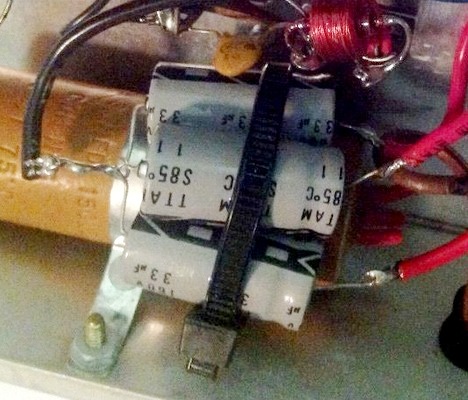

| Use cardboard disks at

either end, push everything into the empty casing,

then seal the ends. I used pieces of beeswax (not

paraffin), and heated it with a

soldering iron

to melt it. Hot glue works, and 5 minute epoxy does a very nice job

and makes the capacitor look like it's right from the factory. Several layers of white glue

(it dries somewhat clear) creates a nice appearance, and is the easiest and cheapest

method. |

|

|

|

|

| If you acquired a set where

the capacitor has already been replaced you can just

make your own. Instead of trying to find capacitors

to fit the cardboard tube, find a cardboard

tube to fit the capacitors. Be sure to make a nice

label. These were printed on a manila envelope to

save ink. The one on the right states that inside is

100% SNAKE OIL |

|

|

|

|

| OK, have it your way. Safety first

and all that. At least make them look nice,

not like the dangerous mess in the photo on the right. |

|

|

| NOTE: With the radio on and

volume turned all the way down, the radio has a

slight 60 cycle hum. There is nothing wrong with the

radio

or your new filter capacitors. |

|

|

|

|

All the capacitors and resistors needed to restore

your radio can be found at

justradios.com.

If you need tube sockets or other

components, try

radiodaze.com. |

|

|

|

|

Stations drift, regeneration

requires constant tweaking |

|

|

|

|

|

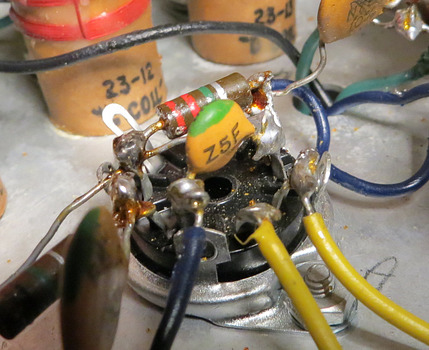

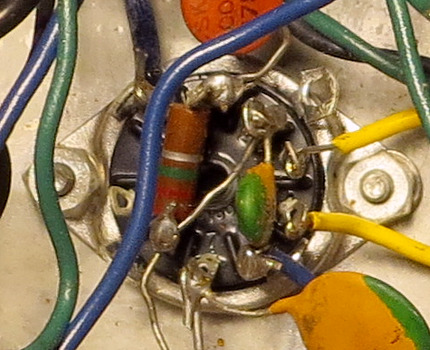

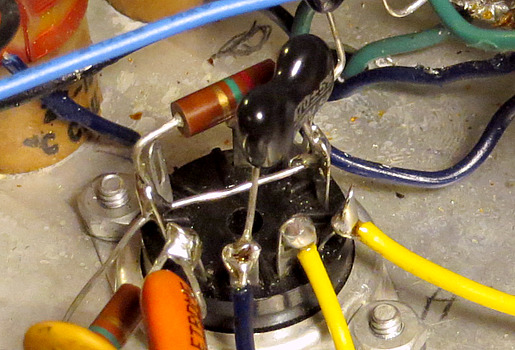

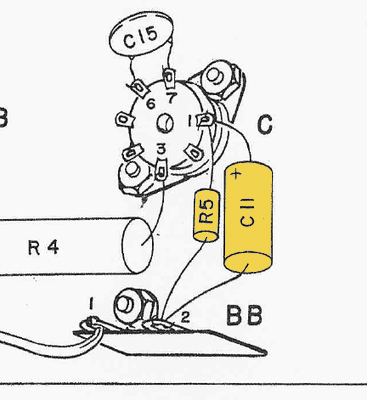

| These pictures, of two

different radios, show the underside of the 12AT7

tube socket, the 2.2 meg grid leak

resistor (R2) and the 470 pF capacitor (C6). The

leads are very short but somehow survived the heat

from the soldering iron. As the tube heats the

resistor and the capacitor, the

values of these components will change, causing a

change in

performance. |

|

|

|

|

|

To improve the radio, replace the resistor and

capacitor. Get the resistor away from the socket

and use a silver mica capacitor. Silver mica caps

are basically immune to temperature

change. Don't attempt this without a spare tube

socket at hand, unless you are very brave. You will

also need to cut some of the blue wires going to the

band switch control to get to the socket.

Don't forget to take the tube out of the socket

before you start working on it. |

|

|

|

|

|

|

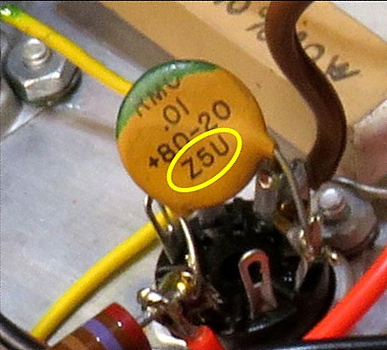

Note:

The capacitors in the KT-135 have two ratings. Most

are rated Z5U. The value of these capacitors is

sensitive to temperature change and can vary as much

as 50% between 50F and 185F.

The capacitor

across the 12AT7 is rated Z5F. This rating signifies the

value is much more precise and there is little

change with temperature (only about 7.5%). However,

a mica capacitor is even more precise and resistant

to temperature change. |

|

|

|

|

|

|

| The value of this 2.2 meg

resistor was actually over 5 meg after being cooked

by the soldering iron. You can tell it's bad just by

looking at it. Guess who did that. ME. This is my

KT-135 from 1972. The radio worked anyway! In the

center photo the resistor has been replaced. The

instructions say to cut each lead to 1/2 inch long.

Cut them to 3/4 of an inch long instead. |

|

|

|

|

|

Low audio volume, but 50C5 tube tests OK. |

|

|

|

|

|

|

|

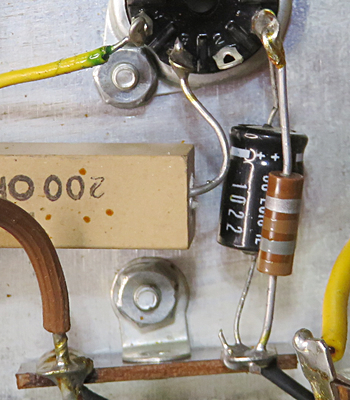

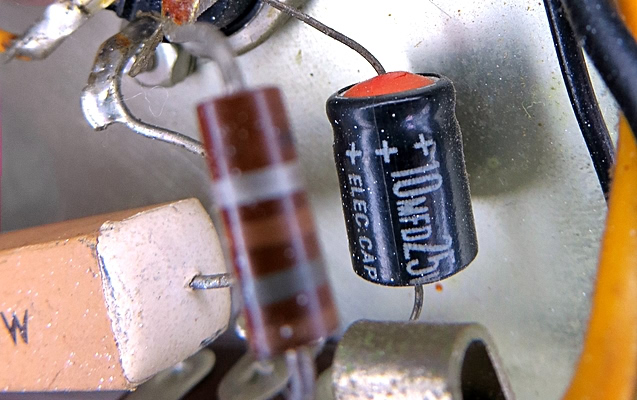

Replace capacitor C11 with a new 10mfd

electrolytic. While it's out, make sure resistor R5 is still

around 180 ohms. |

|

|

|

This

swollen capacitor, from a KT-135 built in 1966, is now 400%

out of tolerance. |

|

|

|

Radio will not oscillate,

regeneration control doesn't seem to work.

Weak 12AT7 |

|

|

| If the

12AT7 drops below 25% of its rating, the radio will

not break into regeneration no matter how high the

regen control is set. |

|

|

|

|

|

A Phillips

JAN 12AT7 and an RCA 6201.

|

A 12AX7 was

sold with the KT-135 from 1959 to 1961. After 1961 a

12AT7 was used. It's easier to control the

regeneration with a 12AT7.

Another designation for the

12AT7 is ECC81. If you find a tube marked "JAN", the

designation stands for "Joint Army Navy." The

12AT7 JAN may be superior, as

well as cheaper.

The 12AT7W, 12AT7WA, and 6201 are ruggedized against

vibration. GE, Sylvania and Tung-Sol made a version

labeled 6679 which was resistant to fluctuations in

voltage. The CV4024 is a

12AT7 made for the British military. All of

these work perfectly.

Stay away from modern

Russian and Chinese versions, as they don't meet the

specifications of a 12AT7. |

|

|

|

|

|

|

|

|

|

|

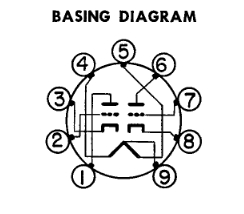

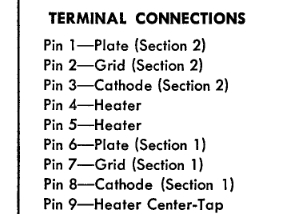

Above is the pinout of

the 12AT7 / 6201. It is

shown as though you were looking at the bottom

of the tube. If the pins on the left are designated 1, 2 and 3,

why is it considered triode 2 and not triode 1?

The answer, which is not an answer, is that the

Radio Electronics Television Manufacturers

Association (RETMA) said triode 1 shall be on

pins 6, 7 and 8. What? WHY? Now I'll never get

to sleep!

The regenerative detector

section of the KT-135 is on pins 1, 2 and 3. If

you test the tube in a tube tester, the 2nd

triode is the important one! |

|

|

|

|

|

|

|

|

Replacing the power cord |

|

|

|

|

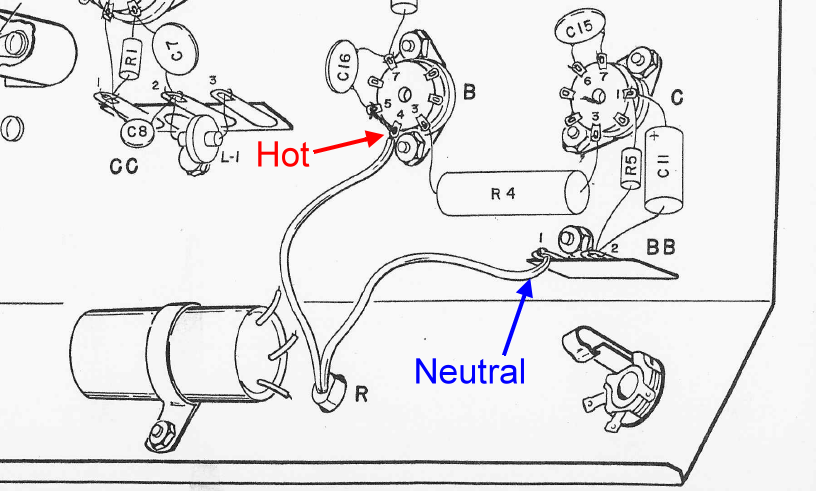

A new power cord will be

polarized. The wide prong is "Neutral" and the

narrow prong is "Hot". (Very useful to know when

rewiring a lamp!) The Neutral wire has a thin stripe

molded into the rubber so you know which wire it is.

Page 16 of the instructions say to turn the

Explor-Air on, then plug it in. Without touching any

part of the radio, check for a voltage between the

chassis and ground. If a voltage is detected,

reverse the plug. Make sure the meter is set to

"AC."

To wire it correctly so that no voltage is present

in the chassis while the unit is on, observe the

picture above. Note that the instructions specify

the set must be ON while checking for voltage. When

plugged in correctly, you'll get no voltage while

the set is on, but you WILL get a voltage while the

set is OFF. However, this voltage won't be directly

from the AC outlet, it has to go through several

capacitors before it gets

to the chassis. |

|

|

|

|

|

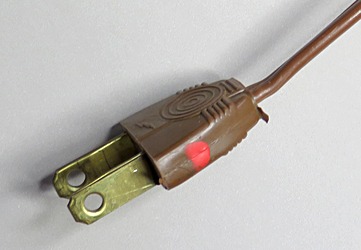

If the new cord is thicker

than the original, carve some of the plastic out of

the strain relief to make it fit. That way, you

don't chew it up with the pliers trying to get it

back in the chassis.

If the old cord is in good

condition you can just follow the instruction in the

manual to mark the "hot" side of the plug. This

side goes into the narrow slot of the AC outlet. (If

the outlet is non-polarized, you will have to mark

it as well.) I

used red paint because a year later I'd forget and

think, "Dolp, I wonder what that dot means." Now

I can just think "red hot." |

|

|

|

|

|

|

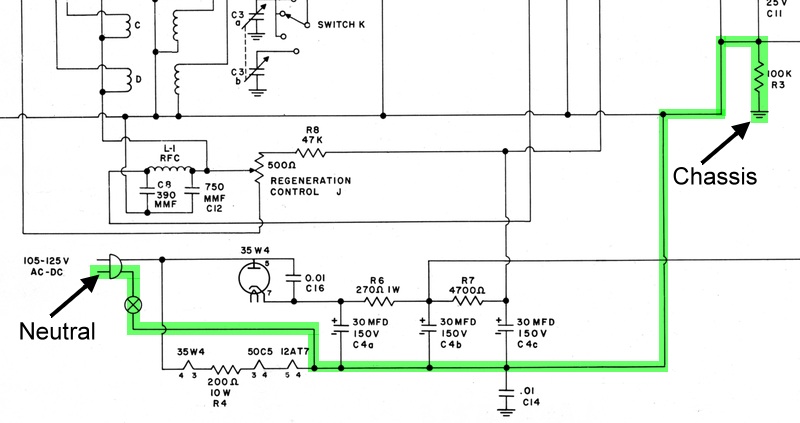

Basically, the plug will be

wired as above. If it's wired the other way, the hot

side of the AC outlet will be connected to the

chassis via the 100K resistor, and you will feel a

mild electric shock if

you touch it while grounded.

This is not a "hot chassis" where one

side of the AC cord is connected directly to the

chassis, so you don't have to worry about it too

much. If you feel something, reverse the plug.

Why isn't the on/off switch on the

hot side? I believe it's because if the

non-polarized plug is plugged in backwards, and the

switch is on the "hot" side, Switch K, a

lug on each coil, and the stators of the

variable capacitors will have a direct connection to the

hot side of the AC outlet even if the set

is off. Like

this.

Since the cabinet was sold separately, some KT-135s

never had one. If a rotor plate on the variable

capacitor was bent and shorted, the whole chassis

would be hot. This sounds a

little far-fetched, but it's the only thing I can

think of. In any case, it's probably not a good idea

to switch the wires to make the radio "safer." |

|

|

|

|

|

|

|

|

|

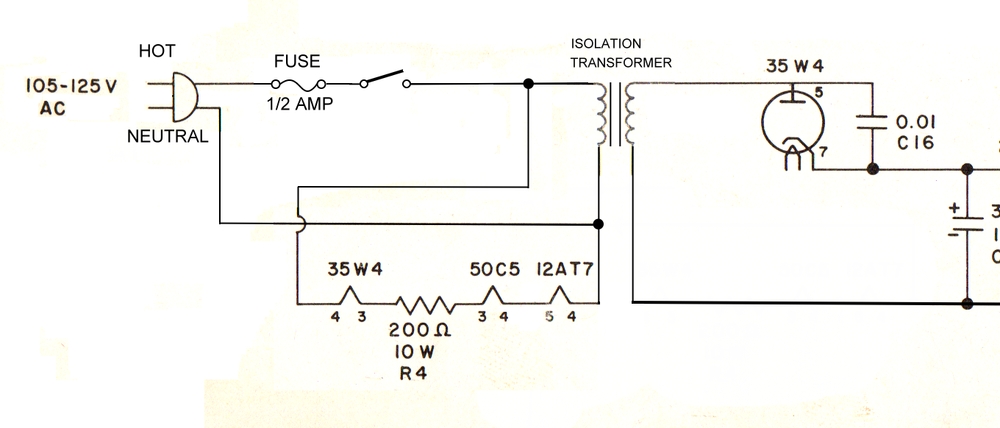

Lawr Salo modified his

KT-135 this way to isolate the radio from the

electric mains. Since the condition of the radio was

poor he had no qualms about drilling some holes in

the chassis and adding the isolation transformer.

"Hot" and "Neutral" are shown in case you're using a

polarized plug, otherwise it makes no difference.

You can also use a cord with a grounded plug, and

ground the chassis if using the transformer. Without

the transformer, grounding the chassis is an

extremely bad idea.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Katie Wasserman's parents

threw her KT-135 in the trash while she was away at college. According to Katie,

the trash can was the near certain fate of 99% of

them. A guy named Karl Keller had one that was

burned up in a house fire. How many are left out

there? |

|

|

|

Note: Under cover of darkness, I carefully

packaged Art's radio and sent it to Karl Keller. I

told Art I'd give his radio a good home, and I did. |

|

|

|

|

|

| |

|

|

|

|

| |