|

|

|

|

|

|

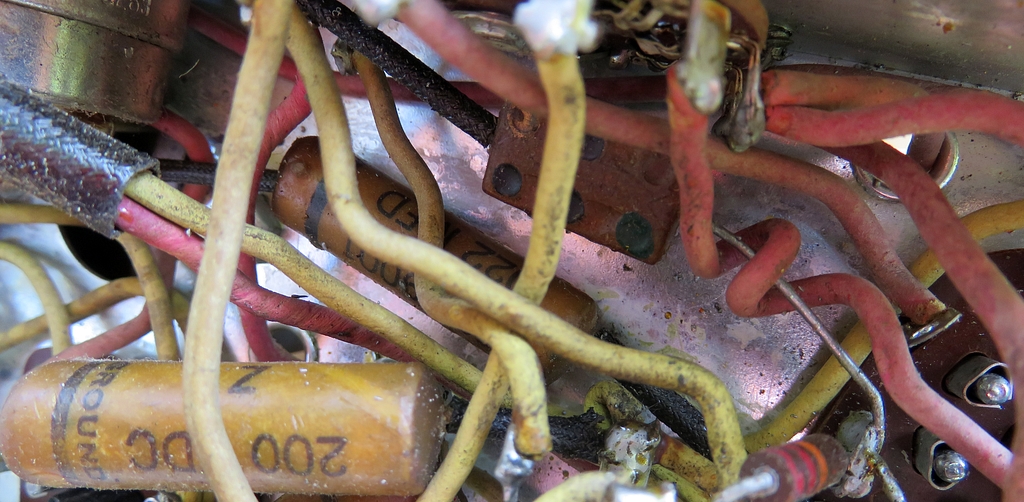

| The underside. WHAT THE

DICKENS??! Who put that huge filter capacitor in

there? It's the wrong value and definitely

the wrong physical size. It's so big that it's

DENTED on the far side from being smashed into

the radio. |

|

|

|

|

|

Rubber coated wire! If you've ever come

across something with an old rubber band around it, and the

rubber band is half disintegrated, you can understand the

folly of coating wires with rubber. If you touch these wires

the insulation will shatter as though it was made of ice.

Notice the red wire on the right, coiled around the

capacitor lead. That's there for a reason. What looks like a

mess under here is actually a carefully planned parts

layout. It's important to place the new parts in

approximately the same place.

There's a paper capacitor buried down there. How are you

supposed to get to that? If it was the year 1960, no

problem, just move the wires aside. But it's 2019 and the

insulation on the wires is petrified. |

|

|

|

|

|

|

|

|

|

Time to get working on the radio, but

first, some cosmic strangeness. Remember the white plug

mentioned on the previous page? I Googled this radio to see

if I could find what the original plug looked like. I found

this picture and thought, "Oh wow, it actually had a white

plug.

Then I looked closer.

This isn't a radio similar to the one I'm working on, this

IS the radio. It's the same radio!!

I got this radio from my son-in-law's mom, who got it from a

guy she works with, who said it belonged to his father, He

wanted $20 for it. So how is it that it was sold at

"Shelly's Sales?" Did the guy's father buy it and somehow

his son ended up with it? |

|

|

|

|

|

|

|

|

|

|

Amazingly, the paper finish protectors behind the knobs survived all

these years. |

|

|

|

|

The radio is going to be restored in reverse order.

I'm going to refinish the cabinet, then work on the radio's

electronics.

I spent more money refinishing the radio cabinet than the

radio cost me. |

|

|

|

|

| The instructions on the Formby's

can were absolutely useless. It says to dip the

steel wool in the Formby's, melt the finish, then

dip the steel wool in the Formby's again and repeat.

All it made was a big mess. Then my gloves melted. |

|

|

|

|

|

|

The way to do it is to melt the finish and wipe it

off with a rag (and wear gloves that don't melt). |

|

|

|

|

|

Adding some contrast to the cabinet. |

|

|

|

|

|

|

|

|

|

|

|

Two quick repairs. The crack in the veneer was held

in with rubber bands. When the Formby's evaporated it had glued

itself back together. |

|

|

|

|

Spraying the cabinet. It was sprayed with

three coats of lacquer, then sanded. Then three more coats

and sanded again. It looked good after that, but for some

reason I decided to apply one more coat. Big mistake.

It had become humid outside and the final coat "bloomed."

Part of the cabinet turned frosty white as water molecules

mixed with the lacquer. I sanded it all out, sprayed it

again, and the same thing happened again. Now, I'm not a

violent man by nature, but... |

|

|

|

|

I thought these knobs would polish up in five minutes

flat. After an hour polishing the first one, I realized they aren't

plastic. They're Bakelite.

A Dremel with a polishing wheel was used on the other

two. |

|

|

|

|

|

Here's the new grille cloth. It's not white. A white

grille cloth wouldn't look right in this old radio. |

|

|

|

|

|

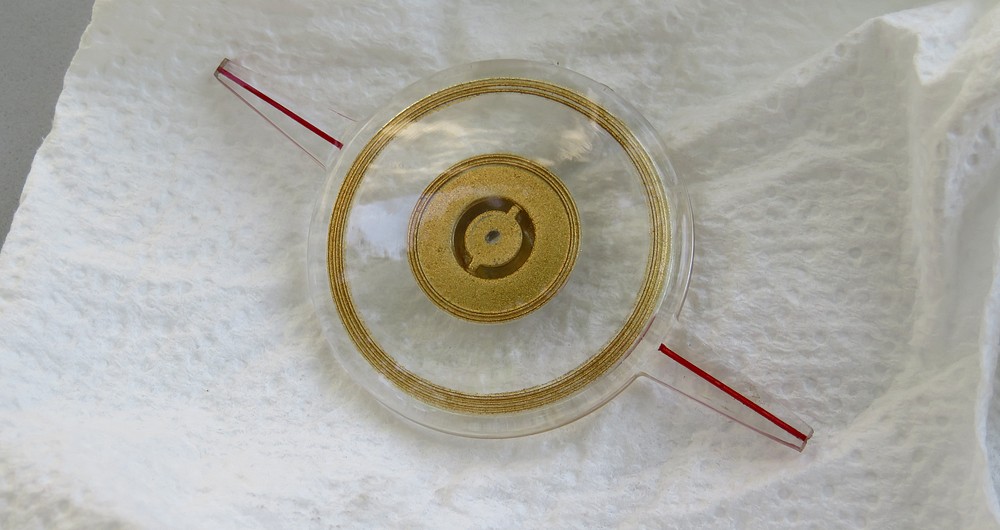

Old and new dial covers. |

|

|

|

|

| After the dial was polished, it

looked brand new. It's crystal clear! What is this made out of?? |

| |

|

| |

|

|

| |