|

1954

Philco clock radio |

|

|

|

|

|

Taking the radio apart and examining the clock. This clock lost five minutes every

fifteen. It's odd for something that's alarmed to move so

slowly. Then I suddenly realized this must

be the very clock the Catholic Church uses to time their masses

on Sunday morning. I knew it was old but I didn't figure on

it being a relic.

Every tube in the set was from a different manufacturer.

12AV6 - Magnavox

12BA6 - RCA

12BE6 - TUNG-SOL

35C5 - Raytheon

35W4 - Philco

All the tubes have something like,

"WHEN REPLACING INSIST ON A GENUINE <brand name> TUBE"

written on them. Imagine going to Lafayette Radio, pounding

your fist on the counter and INSISTING they sell you a Philco tube. |

|

|

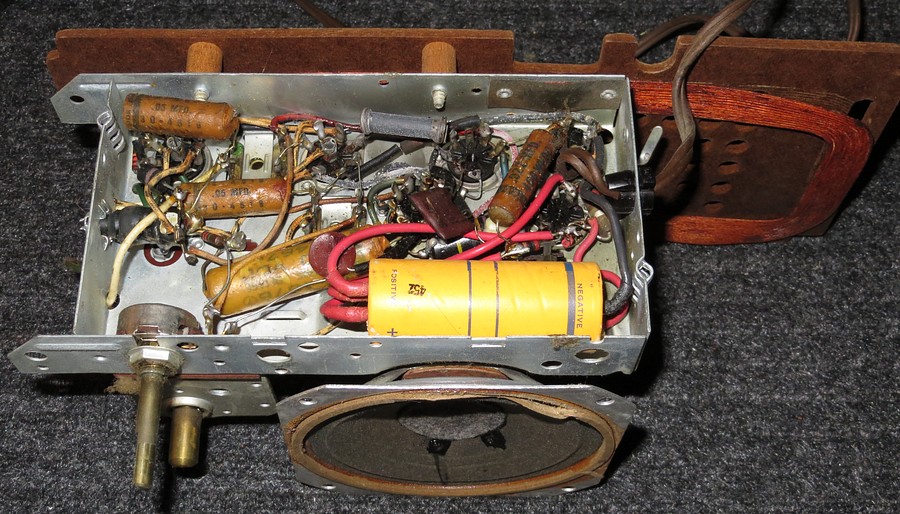

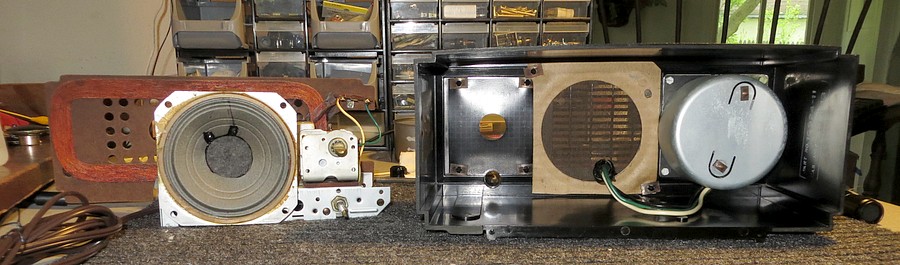

Here is the radio broken down to its

major components.

|

|

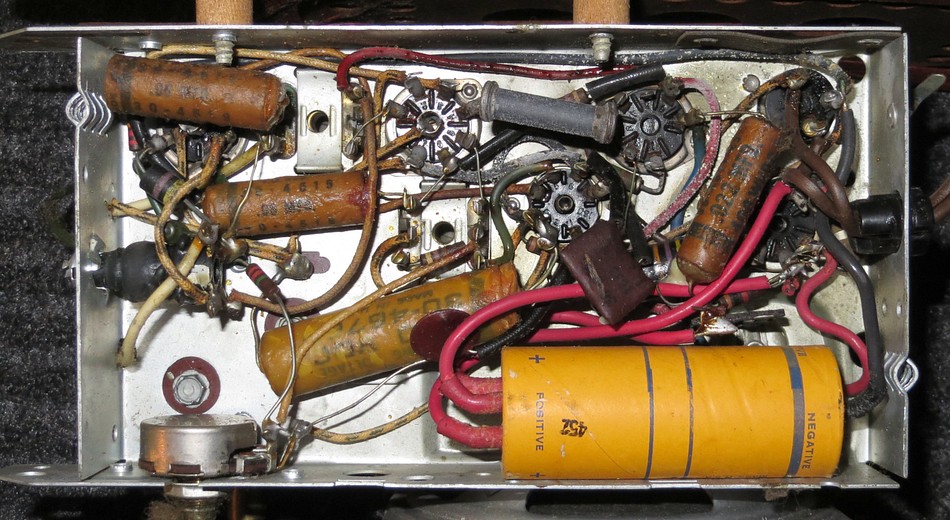

The underside. The chassis is only one

inch deep. Every part was made in the Philco factory in

Philadelphia and all assembled by hand (except for the big

yellow filter capacitor, which is what the repairman

replaced). I think it would have been cool to work at Philco

though I'm sure some of the jobs were absolute drudgery. |

|

|

|

|

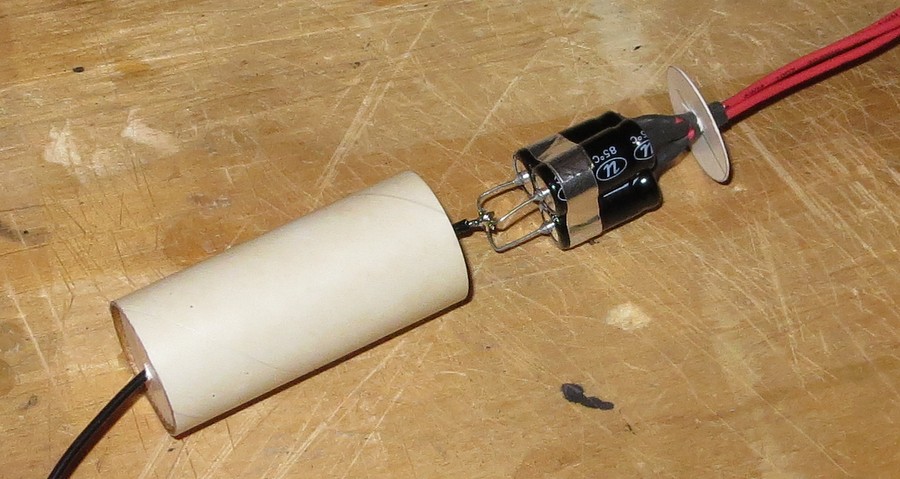

The very first thing done was to

replace the filter capacitor. Since you can't buy

one, I made one. |

|

|

|

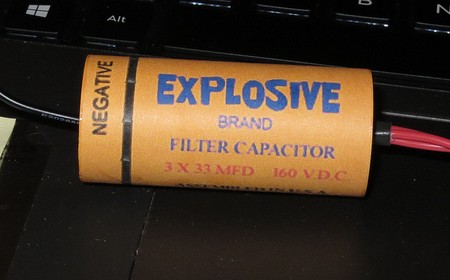

It needed a funny label. |

And it looks pretty scary inside the

radio! |

|

|

Next, the first capacitor to be replaced

was the big ugly one,

because the crack in the wax said, "Put me out of my

misery." |

|

|

|

|

| Lets see what's inside it! The

wax coating is so tough you need a heat gun to melt it. Inside are two

strips of aluminum foil insulated from each other

with a strip of paper, tightly rolled up. The

aluminum is extremely thin, almost like gold leaf.

The outer case is very hard and seems to be made of

rolled paper and glue. |

|

|

|

|

Before and After. Notice a resistor appears near

the center. Explanation below. |

|

|

|

|

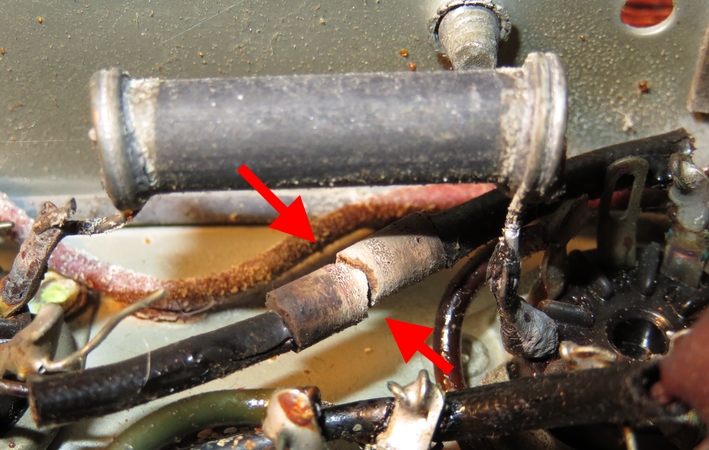

| In the "After" picture a resistor

mysteriously appears near the center of the photo. Here's

where it came from: In the

above photo, the large cylinder is a "tube saver"

resistor that is in series with the tube filaments. It was

designed to start out at 880 ohms and go down to 100 ohms as

it heats up. It gets

very hot.

In this picture the chassis is upside down.

When

it's right-side up the tube saver slowly cooks the small

resistor. The small resistor is rated

at 4700 ohms but tested at 5300 ohms.

It was replaced and moved out of the "oven" and that is what is appearing in the

"After" picture.

|

|

|

|

Eventually, THIS would happen to it. Many Philco

radios have this issue.

|

|

|

|

The "tube saver" gets so hot it burned up its

own solder connections. It's completely out of spec,

having cooked itself half to death. It starts out at 1260

ohms and only drops to 180 ohms. That's fine with me. |

|

|

|

|

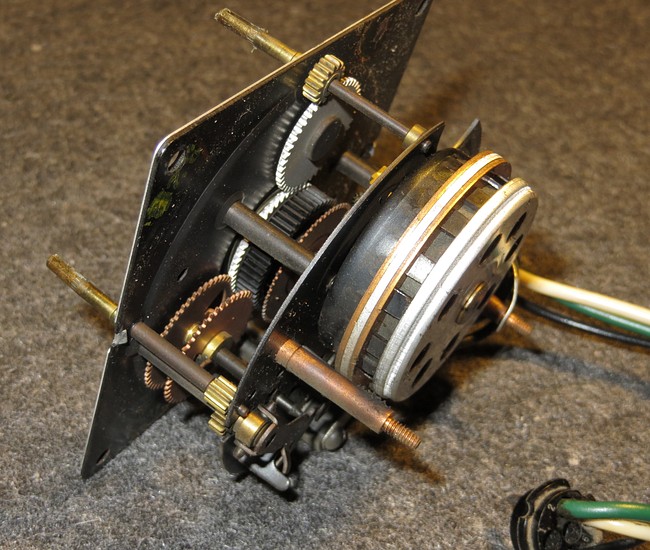

Next, it was time to fix the clock.

No pun intended. All I did was apply sewing machine oil to

all the pivot points and it fixed itself. As a matter of

fact, I oiled the dead clock from the other radio with the

same stuff and it came back to life. Sewing machine oil is

great for this purpose, as it doesn't gum up and turn to

varnish with age.

If I were the Tin Man from the Wizard Of

Oz I would use sewing machine oil on myself. I would drink

it and take a bath in it, because the Tin Man wasn't made of

tin, otherwise he would never have rusted.

|

|

|

|

|

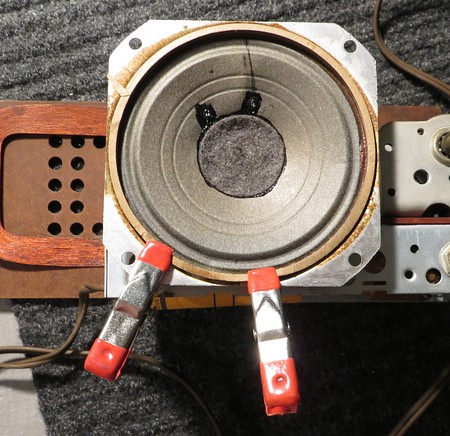

Testing the clock. You can't power the clock

without the radio, and you can't power the radio without the clock. |

|

|

|

|

|

|

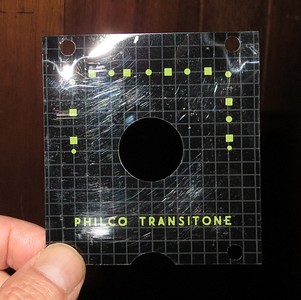

Now it was time to work on the cabinet. Everything

was dirty and scratched. It's 62 years old. |

|

|

|

|

|

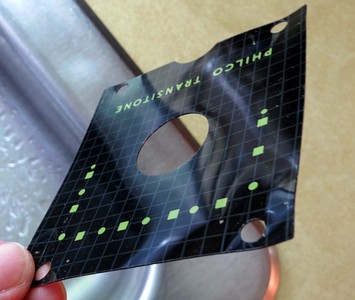

| After

cleaning and polishing. Fortunately, the graphics are

printed under the

clear plastic (left photo). |

|

|

|

|

The cabinet was polished for hours

and hours, then the numbers were repainted on the case. I

almost became obsessed with polishing this thing. Whenever I

had some spare time I'd sit down and polish it.

It was a great excuse to get out of housework. When

asked to lend a hand I

would scream, "CAN'T YOU SEE I'M BUSY??"

They say you can't polish Bakelite, but I did. |

|

|

|

|

|

A few minor fixes were made with some

Elmer's Glue-All. |

|

|

|

The set was

tested and then everything reassembled into the sparkling clean

cabinet.

When I say "tested," I mean I turned it on and it worked. It didn't

actually work all that well. |

|

|

|

|

...but it's safe to touch the controls now.

|

|

|

The set picked up some local

stations but was completely silent between stations. I tried

to convince myself that this was a "feature" but I knew

something was wrong. I wrote to the guys at the

Radio Board.

Ham-er and Bob Weaver asked what kind of

voltage I was getting on the Automatic Volume Control (AVC).

I turned the set on to measure the AVC voltage and it was stone

dead, except for a sizzling noise at full volume. |

|

|

|

|

|

|