|

Lance Borden "Armstrong one tube

Regenerative Receiver"

Review |

|

|

|

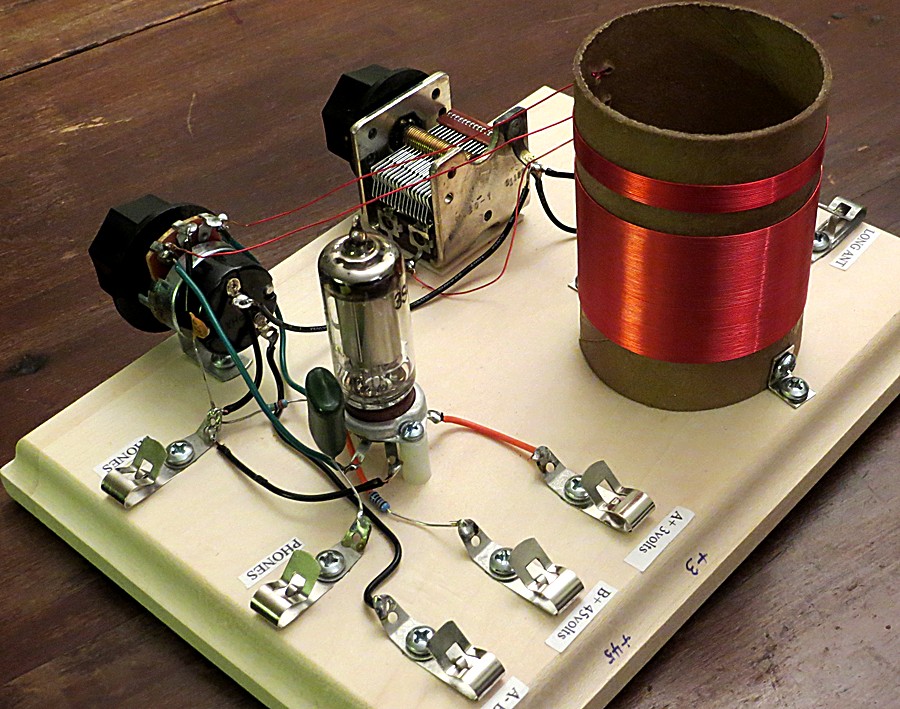

As

stated on the Borden Radio website, the kit contains all high quality

parts. The pre-drilled base is furniture grade pine, and the heavy

cardboard coil form is already coated in polyurethane. All parts are

included, even the hookup wire and felt "feet" for the bottom. You'll

need to supply your own batteries; two "D" and five 9 volt.

|

| Solder lugs

are included with the kit to make hookup easy, and the connections will remain

tarnish free for the life of the set (virtually forever.) The labels are also provided. |

|

|

|

| The kit comes

with a ten page pamphlet. In this pamphlet, along with the instructions

to assemble the kit, are a brief history of the vacuum tube, early

radio development and notes on Edwin Armstrong and his invention of the

regenerative radio receiver. There is also an explanation of how the

radio works, what the vacuum tube does, and how to operate the radio.

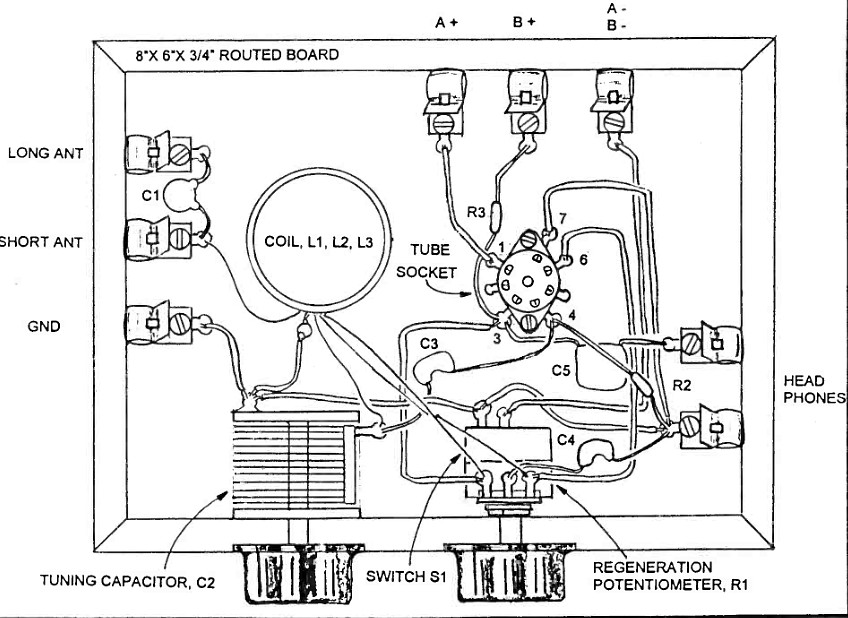

There is a very nice schematic diagram of the radio with a parts list,

all on one page. |

|

|

| Many one tube regen

radios have 45 to 90 volts B+ going through the headset. This one

doesn't. There are no problems

with stray capacitance in the headset cord to throw you off while

tuning a weak station. Also, an audio amplifier can be connected

without altering the circuit. It is surprisingly immune to hand capacitance

while tuning it. |

|

|

|

|

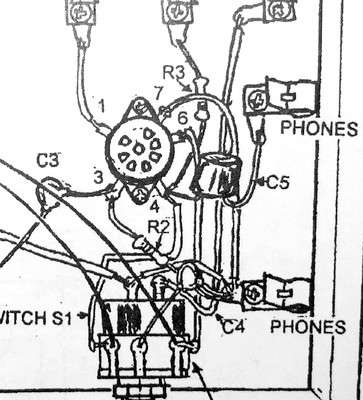

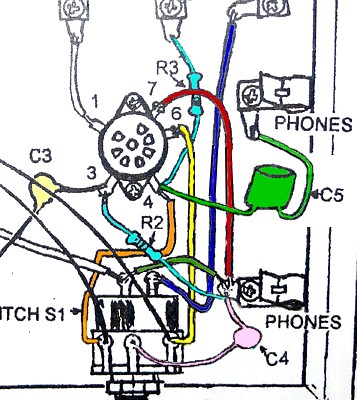

| Assembling the

set was a bit of a challenge because of the instructions. The image to the left is a part of the

wiring diagram. Try to find capacitor "C4" in the drawing. This, and a black and white photo are what you use to

wire the set. We ended up referring to the schematic diagram time and

again. Adding color and moving C4 and C5 in the drawing makes it readable. |

|

|

|

|

Illustration from Electronics

Handbook Vol. XIX

|

If you contact Lance

Borden he'll send you a copy of the magazine article he

wrote for "Electronics Handbook Vol. XIX." In it is a much clearer

drawing of the radio. Unfortunately, we didn't have this at the

time.

UPDATE: See the link on the previous page to view the magazine.

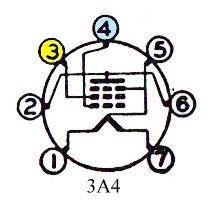

Actually, pins 3 and 4 are reversed in this drawing (observe

the connection of R3 in upper drawing), so perhaps it was good that

we followed the schematic. The kit came with a 3S4 vacuum tube. The drawing in the magazine uses a 3A4 tube, ergo the reversed

connections. |

|

|

|

|

|

|

|

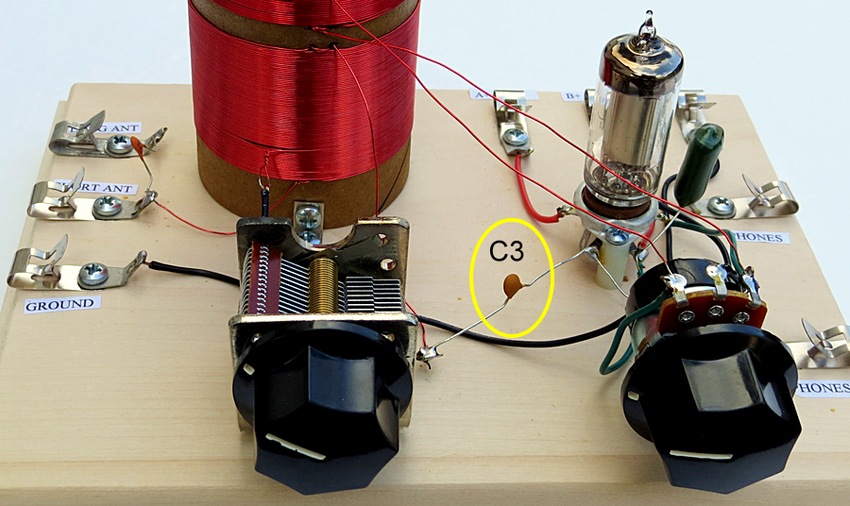

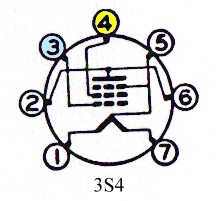

Finished Radio. (Click to enlarge) |

|

|

|

|

|

|

Construction tip - place the variable capacitor on the

board so that capacitor C3 can reach it. |

|

|

|

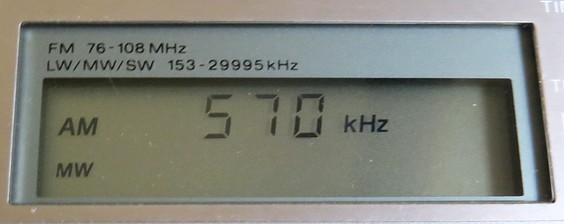

| Now we come to

an unexplained problem with the set. The low station on the AM dial

here in the Philadelphia, PA area is WFIL, AM 560. The radio wouldn't

tune down that far. Why not? Did Matt miscount the turns while winding

the coil? The number of turns on the coil were counted THREE times and

were found to be perfect. (20 turns, a tap, and 55 turns, for a total

of 75 turns of wire). So what exactly was it tuning down to? |

|

| |

|

|

| That was easy to

figure out. A regen radio transmits on whatever frequency it's tuned

to. All that was needed was to use a radio with a digital display and

listen to the squeal from the regen radio. In this case, it tuned down

to 570 kHz. |

|

|

| Method used to

count the turns of a coil: A blunt hard object is wiped over the wire

and the number of "clicks" are counted. (The corner of a credit card

works well.) This can be an exercise in concentration! It is also

useful while winding the coil if you become distracted while counting.

In this case,

the number of turns was exactly what the instructions called for.

20 turns, a tap, then 55 more turns.

|

|

|

|

| After looking at

some radio websites and online coil calculators, it became apparent

there weren't enough turns to tune down to the low end of the band. The

coil was removed from the set and a new coil was wound on the same coil form. The

new coil has 21 turns, a tap, and then 61 more turns, for a total of

82

turns. 26 gauge wire was used, same as the original. |

|

|

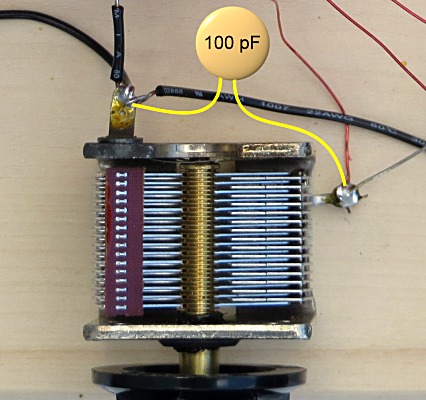

With the new coil, the

radio tunes from 540 to 2000 kHz. I was surprised to hear Morse code

up at the higher end.

The big question is this: Do every one of these Borden radios have the

same problem? There are photos of seven completed radios of this design on

the xtalman website, and in 2004 the set appeared in CQ Amateur Radio

magazine. Perhaps hundreds have been built. Did we get the oddball?

It turns out we didn't. In a radio forum a guy asked

why he couldn't tune in a station at 580 kHz on the set. One answer

was to put a capacitor of 100 pf across the tuning capacitor.

That would be easier than rewinding the coil!

|

|

|

|

|

|

|

Like this. |

|

|

| Well, it works now. Troubleshooting this was all part

of the fun of building it! |

|

|

|

|

|

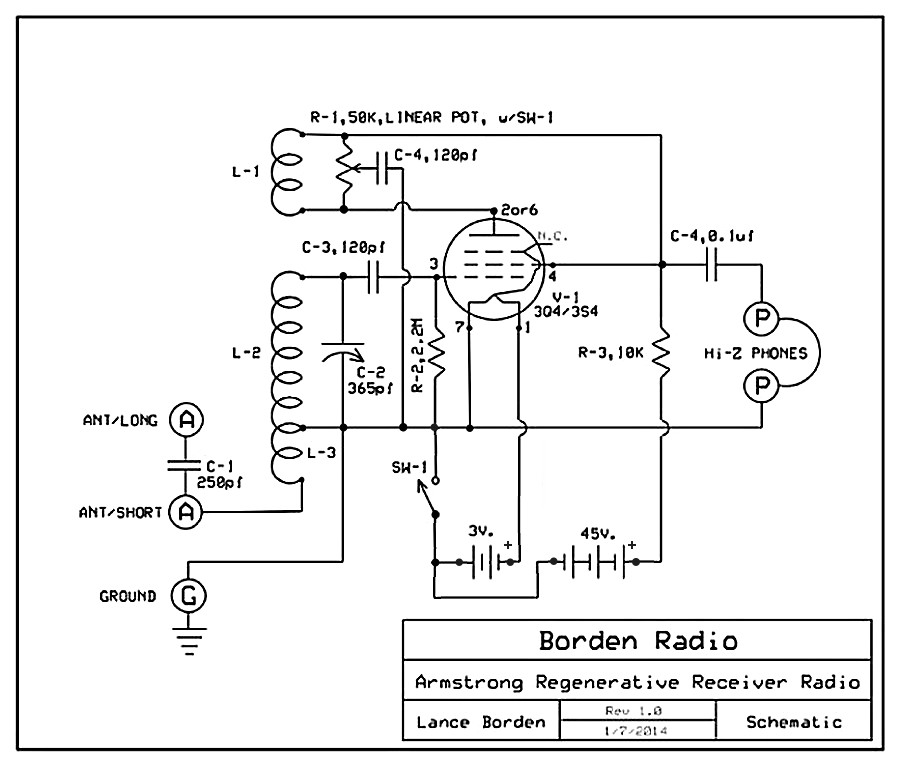

The schematic, drawn by

Mike Peebles. Number of turns for 2"

diameter coil.

|

|

| Note: if using a 3A4, connections on

pins 3 & 4 of 3A4 tube are reversed compared to 3S4/3Q4. |

|

|

|

| |

|

|

|

| |

FYI, tube diagrams

show the pins as viewed from the bottom of the tube.

Pins 3 and 4 are reversed on 3A4 vs. 3S4 as noted above.

The 3A4 was designed 2 years after the 3S4 and has a higher output. |

|

|

|

|

|

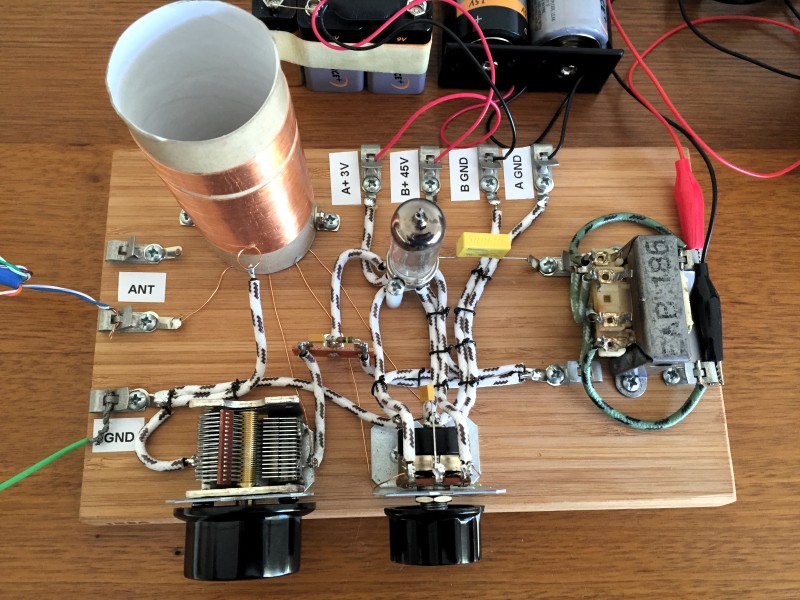

A Borden clone with alternative filament hookup.

The "Shoelace Radio" |

| "\Milorad" built this

clone using a 3A4 tube. The object on the right is an impedance

matching transformer for the headphones. |

|

|

|

|

|

|

|

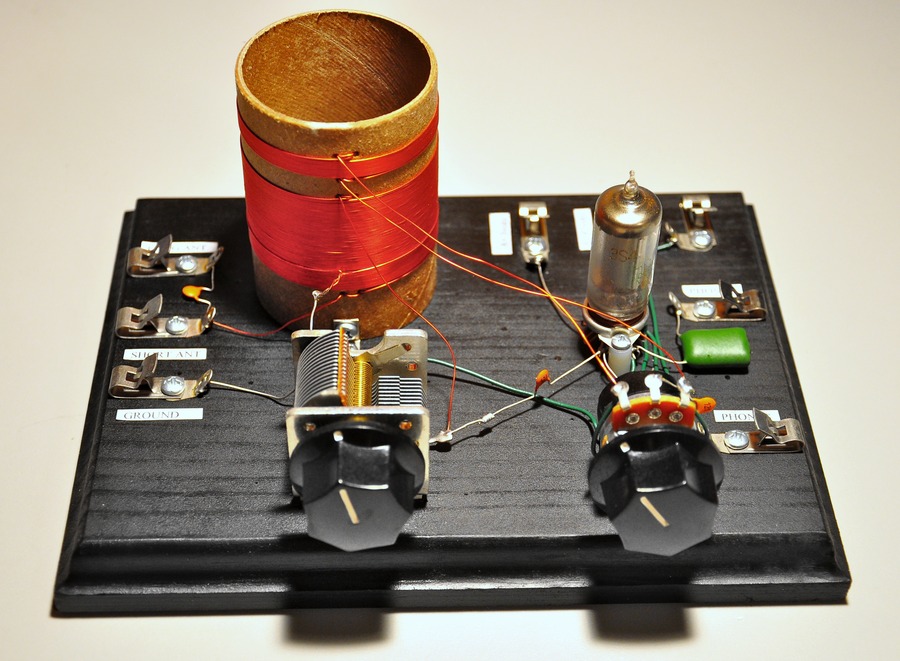

The radio as built by Lance Borden, from the cover of

Electronics Handbook magazine, |

|

|

|

|

|

|

This beautiful set was built by Felix Schaffhauser of

Switzerland. |

|

|

|

|

|

|

A painted base. Very nice! |

|

|

|

|

|

|

|

| |